SmartRoller Cloud Compaction Management System

Product Summary

- i-Con

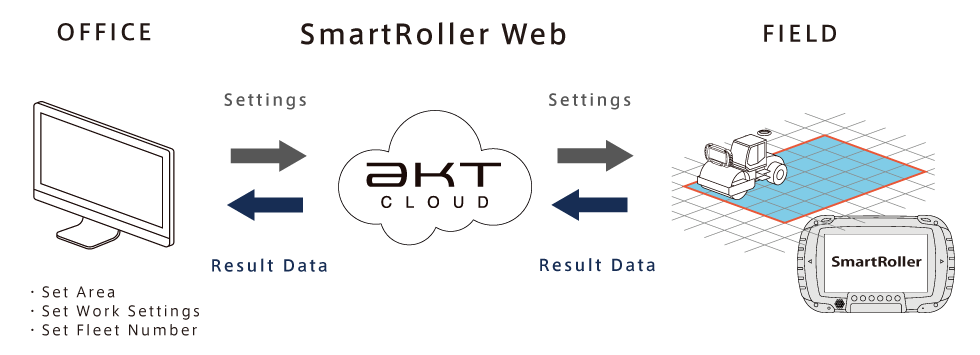

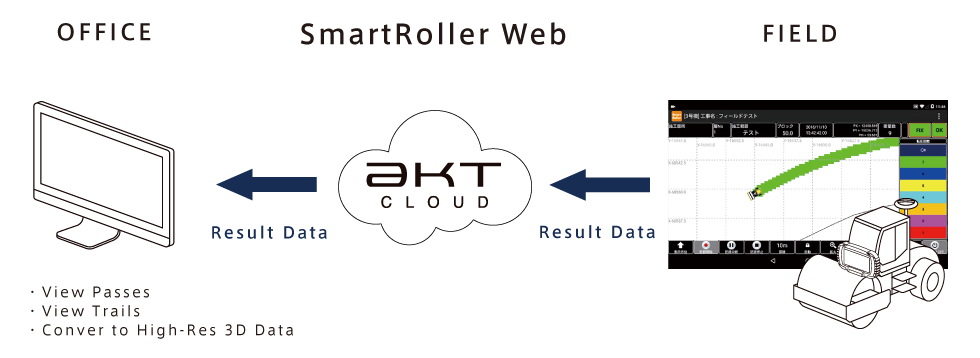

SmartRoller is a compaction management system that utilises GNSS and TS to get trailing data points to keep track and manage compacted areas. Incorporating ICT into the workplace by utilising cloud technology to store and access operation data, in-effect improving workplace efficiency, ease of operation and reduction in labour cost.

Main Features

SmartRoller Main Features

- Utilising cloud server for a centralised management system

- Improve compaction quality by keeping track of compactions

- 3D Datapoint Output (3D Graphing Software Required)

- Utilising the Rugged Multi-Purpose HDT320

Operation Management in One

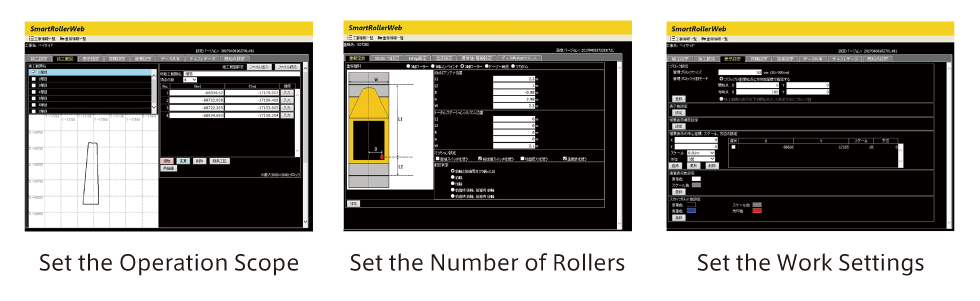

Access, Plan, Manage, Analyse and Process compacting operation seamlessly by utilising the i-Construction application.

All the initial settings and planning are done remotely and streamed directly to the cloud where the task can be selected by the operator in the field. The operation results can also be downloaded from the cloud remotely for analysis with ease.

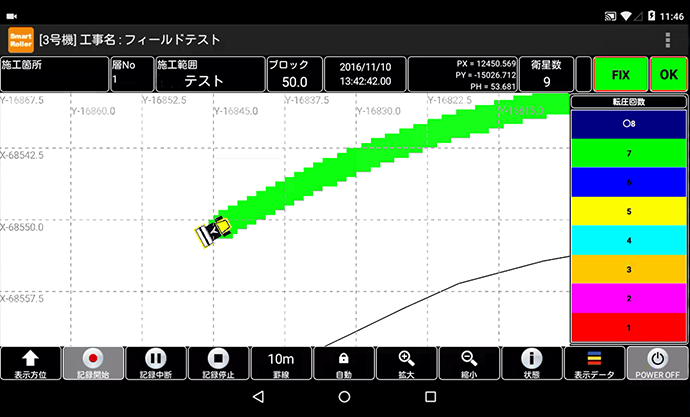

Construction scope and various settings (screen image)

Increase Overall Work Quality

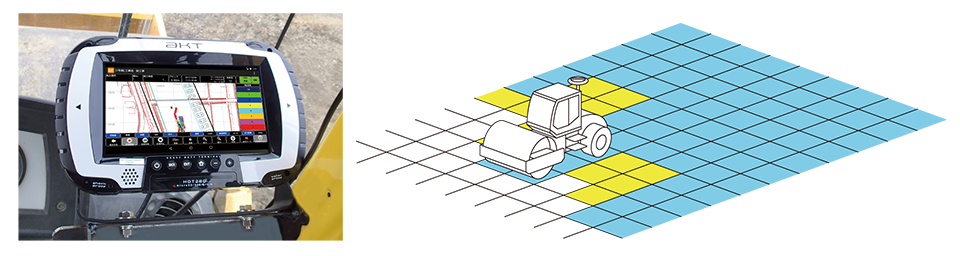

Real-Time Compacting Status Monitoring

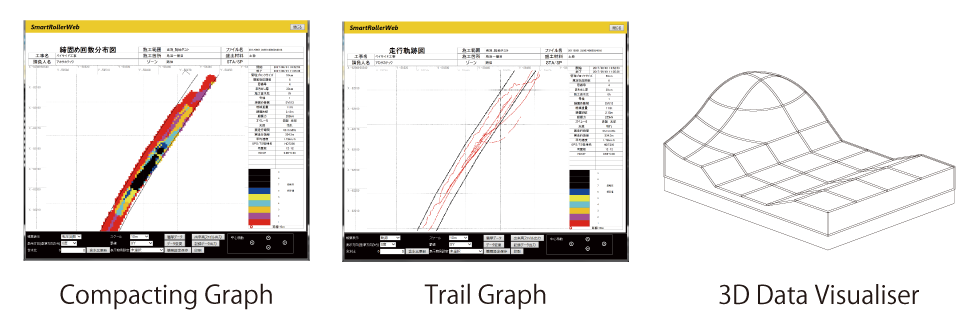

Designed with ease of use and readability in mind, keeping track of compaction can be done easily at a glance.Receive unparalleled feedback with real time roller positioning and compaction status. In combination with various presets and regulated compaction methods, accurate progress tracking is achieved, reducing human errors and misses.

Operation data can be viewed anywhere with ease to be processed, printed or visualised in 3D graphs.

Report and data output (screen image)

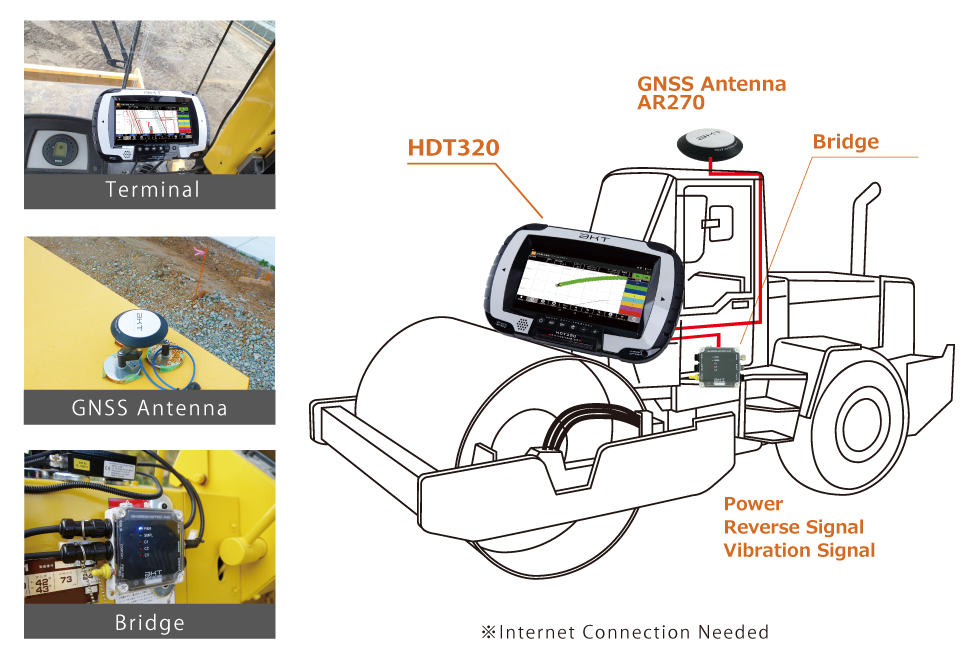

Rugged Multi-Purpose HDT320

Designed for the rugged, unforgiving environment of the worksite, the HDT320 is a tablet designed with the user and the workplace in mind. Equipped with 2 dual-frequency GNSS modules, tough IP67 rated casing, vibration and impact resistant body, the HDT320 will be an indispensable workhorse equipment for multitudes of different operations.

Dual-Frequency RTK-GNSS Receiver Terminal HDT320 [Page Link]

Setup Example

The HDT320, replaces traditional needs of a standalone GNSS Receiver, Communication Device and Storage in this scenario.

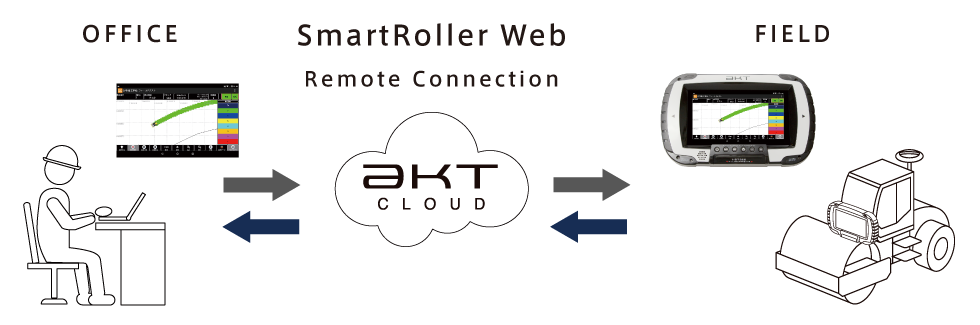

Fast Remote Support

Set, check and troubleshoot problems remotely

Whether it is a dedicated support team or operation manager, in-house or out-sourced, remote support such as change of settings, checking operation status and troubleshooting can be done quickly and easily.

SAKAI Compaction Meister Compaction System

In the following clip, our company has created a video in partnership with SAKAI to demonstrate how SmartRoller is used in tandem with SAKAI’s Compaction Meister and its benefits.

Recommended Pairings

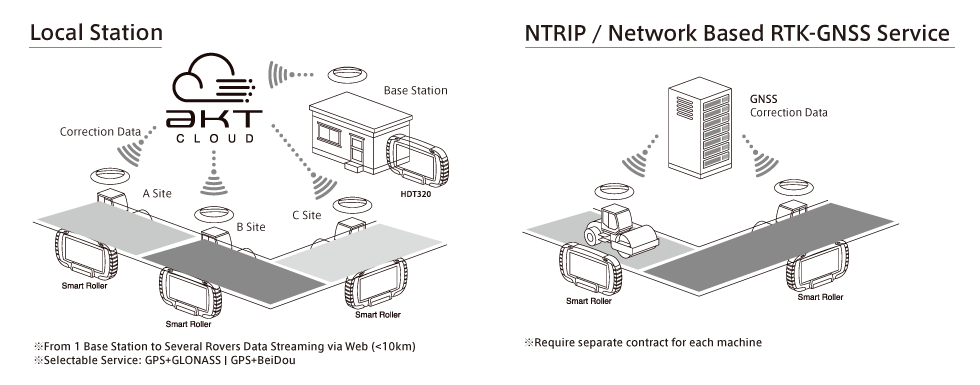

RINQ Dual-Frequency GNSS Correction Service

Use HDT320 as a reference station (Base Station) to locally stream GNSS Correction Data to nearby Rover Stations for high accuracy high precision Dual-Frequency RTK Positioning.

GNSS Correctional Streaming Service RINQ [Page Link]

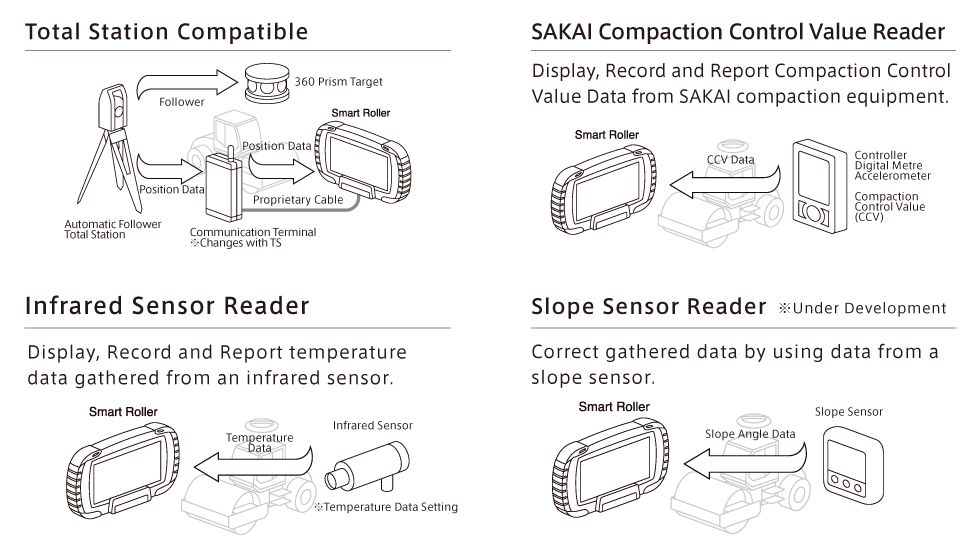

Other Data Utilisation

- TS (Total Station)

- SAKAI CCV Data (Read, Display, Record, Report)

- Infra-red Temperature Data (Read, Display, Record, Report)

- Tilt / Slope Data for Compaction Height Corrections

Other products information